The Institute of Advanced Structure Technology has played a leading role in multiple cutting-edge testing technologies, including ultra-high/low-temperature mechanical property testing, ultra-high nanoindentation testing, in-situ mechanical testing with high-temperature CT, thermo-mechanical-oxygen coupled testing, ultra-high strain rate dynamic testing, high-temperature stealth and radar-absorbing material testing, as well as in-situ mechanical/electrochemical property testing for power batteries. The Institute has independently developed over 20 sets of specialized testing equipment, such as the CT-based in-situ mechanical testing system, 2600°C oxygen partial pressure mechanical tester, 1600°C nanoindenter, industrial CT testing system, and high spatiotemporal resolution dynamic mechanical coupling failure analyzer. These innovations have provided critical testing methodologies and instrument support to numerous research institutions and universities serving aviation, aerospace, maritime, and army applications.

n In-situ testing instrument for internal deformation fields and damage of ultra-high temperature materials

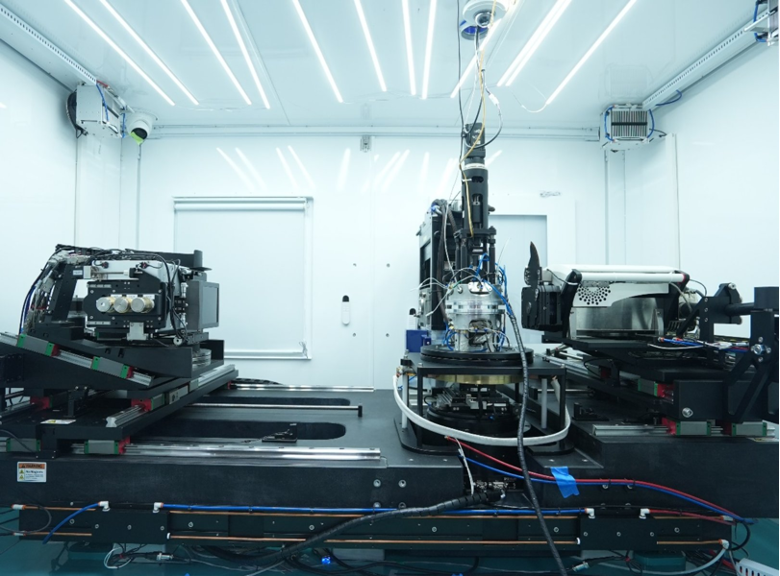

An independently developed in-situ testing instrument based on movable X-ray imaging has been established to analyze internal deformation fields and defect damage in materials under ultra-high temperature conditions. This apparatus enables in-situ computed tomography (CT) examinations under mechanical loading conditions, including tension, compression, bending, shear, and indentation, at temperatures reaching up to 2200°C in inert atmospheres and 1800°C in oxidative environments. The instrument facilitates accurate measurements of internal deformation fields, extraction of damage evolution parameters, and quantitative strength analyses of ultra-high temperature materials. Its performance metrics surpass those of comparable instruments reported in current literature. On one hand, the instrument provides critical scientific tools and experimental methodologies for advanced interdisciplinary research in mechanics, materials science, aerospace engineering, and nuclear energy engineering. On the other hand, it offers robust experimental techniques, empirical data, and technical support essential for designing and developing ultra-high temperature materials and structures for major national engineering projects and defense equipment.

Fig. 1 Independently Developed In-situ Testing Instrument Based on Movable X-ray Imaging for Internal Deformation Fields and Defect Damage of Ultra-high Temperature Materials

n Dynamic thermo-mechanical failure tester with high spatiotemporal resolution

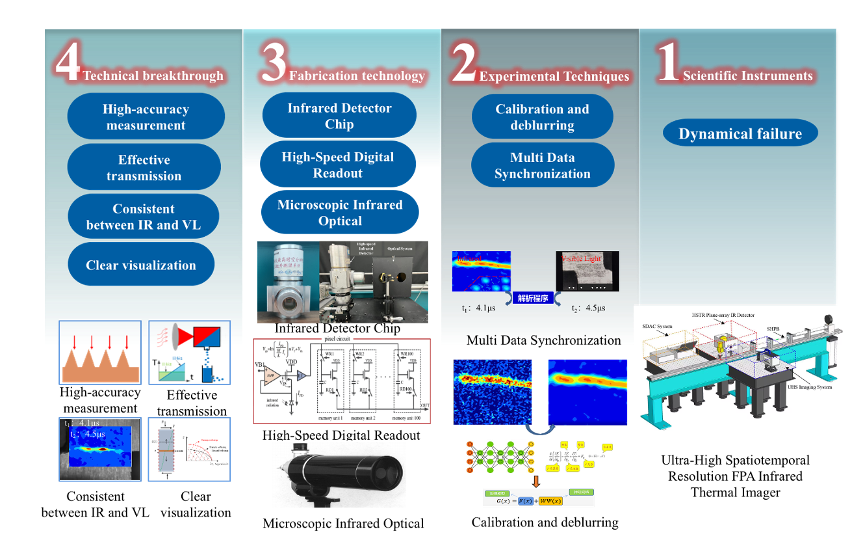

The independently developed fully-domestic 64×64 array infrared detector achieves continuous storage of 100 frames at a 1MHz sampling rate. Coupled with a 2× optical system, it delivers 25μm spatial resolution and a temperature measurement range of 25–800°C, with all specifications surpassing currently reported comparable instruments.

Integrated with acquired high-speed optical equipment (7M pixels), this system represents the first microsecond-level high spatiotemporal resolution synchronous dynamic loading platform capable of simultaneous deformation field and temperature field measurements. It meets research and testing demands across multiple disciplines including dynamic fracture, dynamic friction, seismic mechanics, high-speed mechanical processing, and explosive stability analysis.

Fig. 2 Proprietary Thermo-Mechanical Dynamic Failure Testing System

n NDT of composite structural damage for mechanical systems

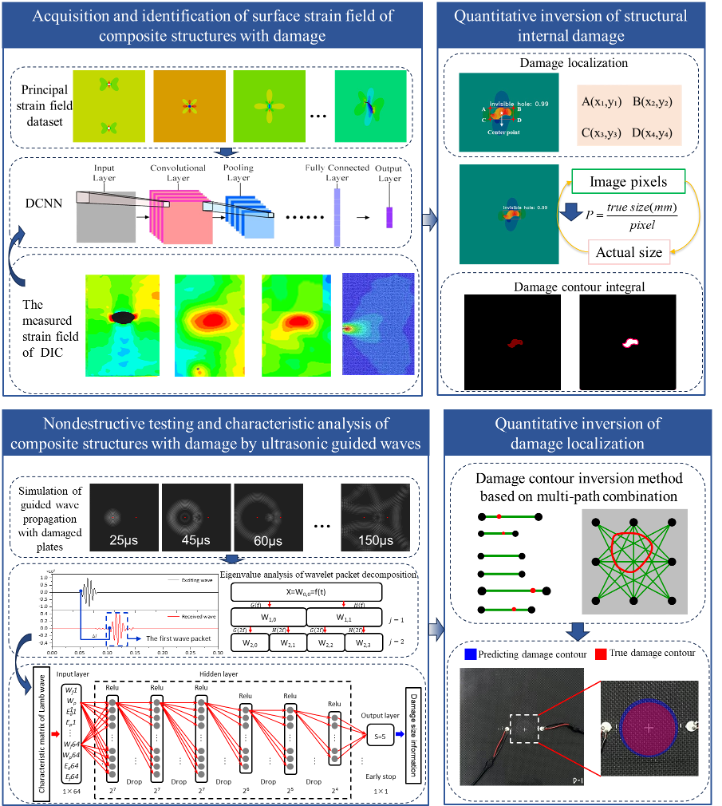

By integrating Lamb wave guided-wave detection with structural surface strain field inversion methods, and leveraging computer deep learning technology, we developed a damage identification and real-time structural performance inversion network model that combines surface strain field data with Lamb wave characteristic parameters. This model elucidates the influence mechanisms of various damage types on both external strain fields and Lamb wave features under typical loading conditions, enabling high-precision prediction of internal damage types, locations, and geometric dimensions in composite structures.

Fig. 3 Damage detection and inversion for composite structures based on surface strain field data and Lamb wave characteristics