Three-dimensional tubular braided composites, known for their high specific stiffness, high specific strength, and excellent design flexibility, have been widely utilized in critical load-bearing components across aerospace, automotive manufacturing, and medical devices. However, during the manufacturing process, unavoidable issues such as cross-sectional variations in the reinforcement phase (fibers) and defects in the matrix phase (resin) may occur. Additionally, these composites are often exposed to various environmental conditions, such as extreme high and low temperatures, during practical applications. These factors can significantly impact their mechanical properties. Therefore, accurately predicting the mechanical behavior of these structures under different environmental conditions is crucial for ensuring their performance and extending their service life.

To address this issue, Professor Li Huimin from Institute of Advanced Structure Technology, BIT, under the guidance of Professor Fang Daining, conducted the research by combining composite mechanics and multi-scale analysis methods. The related findings were published in the international top-tier journal Composites Science and Technology under the title "Prediction of mechanical properties of 3D tubular braided composites at different temperatures using a multi-scale modeling framework based on micro-CT."

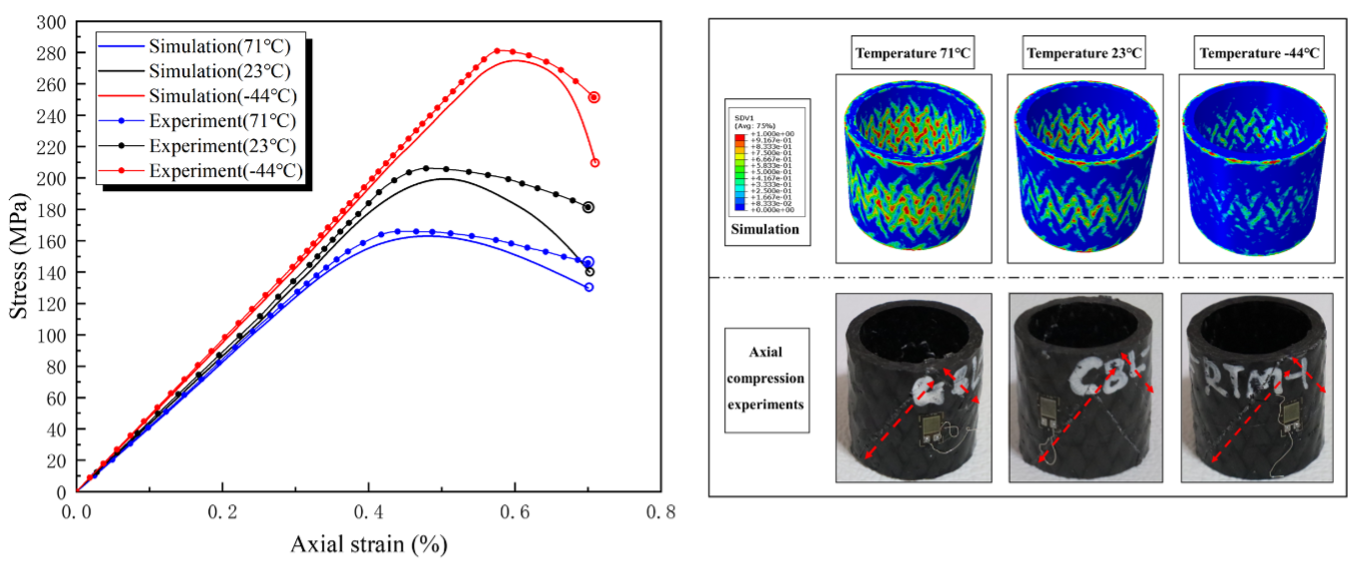

The research work, based on a micro-CT multi-scale modeling framework, fully considers the real characteristics of fiber bundles, fiber morphology, and defects formed during the manufacturing process. A trans-scale finite element model was established for the elasto-plastic damage of 3D tubular braided composites, accounting for temperature effects. By comparing with experimental results, the model successfully simulated the mechanical properties at both the micro- and macro-scales under different temperatures. This study provides a novel micro-CT-based trans-scale modeling method for the design and manufacturing of such structures.

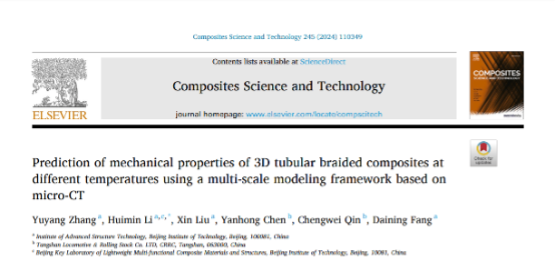

Fig.1. Manufacturing and testing system of the specimen

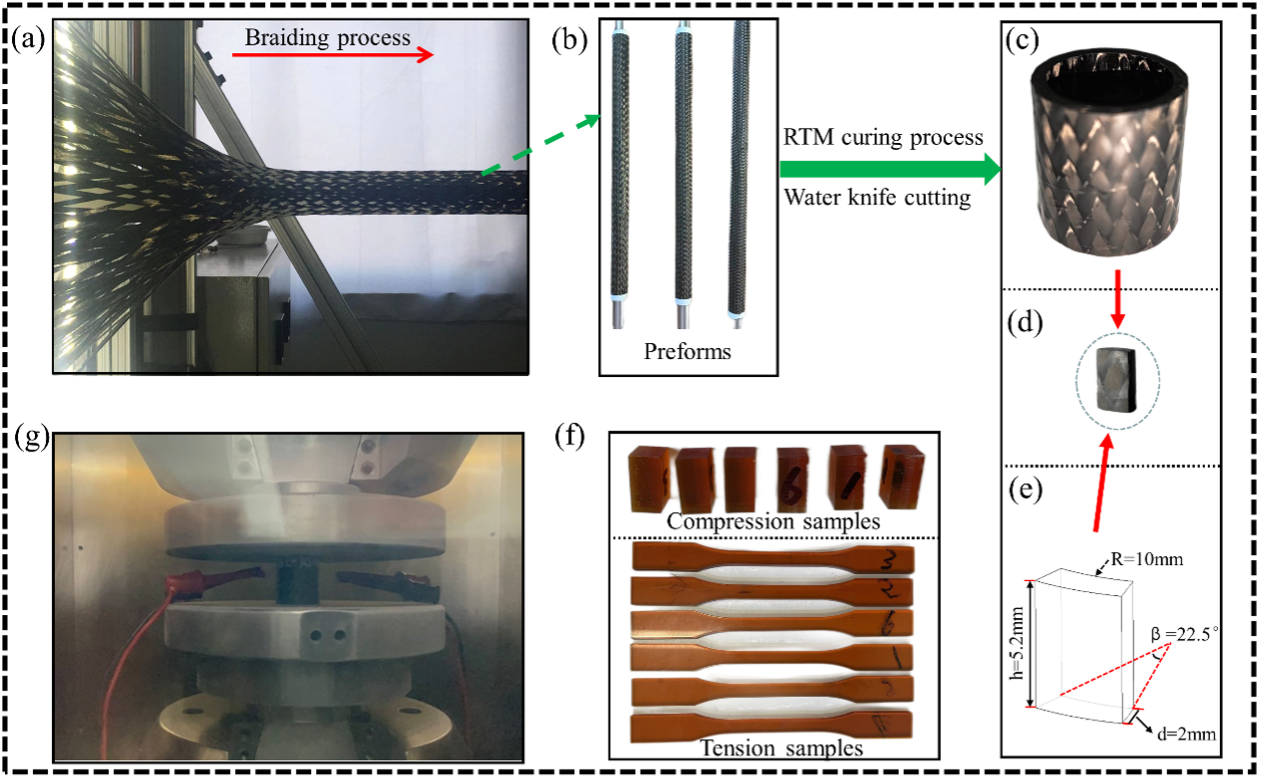

Fig.2. Establishment of the matrix RVE

Fig.3. Establishment of the yarn RVE

Fig.4. Finite element model of 3D tubular braided composites: (a) Slicing the sample using micro-CT; (b) Mapping the meso-scale model to the macro-scale model; (c) Reconstruction of the macro-scale finite element model.

Fig.5. Finite element simulation and experimental results of 3D tubular braided composites at different temperatures.

Original link:

https://doi.org/10.1016/j.compscitech.2023.110349.

Professor Li Huimin has conducted a series of research works focusing on the multi-scale mechanical behavior of 3D braided composites and their structures. The related research achievements are as follows:

[1] Lei Ge, Huimin Li*, Jiehua Zhong, Chun Zhang, Daining Fang. Micro-CT based trans-scale damage analysis of 3D braided composites with pore defects [J]. Composites Science and Technology, 2021, 211:108830.

[2] Lei Ge, Huimin Li*, Yuyang Zhang, Jiehua Zhong, Yi Chen, Daining Fang. Multiscale viscoelastic behavior of 3D braided composites with pore defects [J]. Composites Science and Technology, 2022, 217: 109114.

[3] Yuyang Zhang, Huimin Li*, Xin Liu, Yihang Gao, Chengyu Guan. Trans-scale elastic-plastic damage analysis of 3D tubular braided composites with void defects[J]. International Journal of Solids and Structures,2023,274:112288.

[4] Lei Ge, Huimin Li*, Yihang Gao, Ruishen Lou, Kai Liu*, Jiehua Zhong, Daining Fang. Parametric analyses on multiscale elastic behavior of 3D braided composites with pore defects [J]. Composite Structures, 2022, 287:115332.

[5] Yuyang Zhang, Huimin Li*, YihangGao, Ruishen Lou, Lei Ge, Daining Fang. Multi-scale modeling and elastic properties prediction of 3D four-directional tubular braided composites[J]. Composite Structures, 2022,292:115632.

[6] Lei Ge, Huimin Li*, Huayong Zheng, Chun Zhang, Daining Fang.Two-scale damage failure analysis of 3D braided composites considering pore defects [J]. Composite Structures, 2021, 260:113556.

[7] Lei Ge, Huimin Li*, Baosheng Liu, Daining Fang. Multi-scale elastic property prediction of 3D five-directional braided composites considering pore defects [J]. Composite Structures, 2020, 244:112287.