BIT scholars designed and 3D printed novel ceramic composites and structures for electromagnetic interference shielding in the terahertz band.

Terahertz electromagnetic waves have broad application prospects in the fields of imaging, guidance, communication, medical treatment, and non-destructive testing. The electromagnetic pollution and interference issues brought about by these waves are becoming increasingly significant, necessitating the development of high-performance electromagnetic shielding materials in the terahertz band. Currently, precursor-derived ceramics have been widely reported for their application in microwave electromagnetic wave shielding, but their shielding performance in the terahertz band has received less attention. Moreover, the next generation of terahertz electromagnetic shielding devices are often complex and irregularly shaped, and the traditional forming methods for precursor-derived ceramics usually only produce powders, thin films, or simple blocks, which are difficult to meet the application requirements. Stereolithography 3D printing has been successfully reported for the forming of precursor-derived ceramics and their components. If terahertz electromagnetic shielding materials based on precursor-derived ceramics can achieve stereolithography 3D printing, it will greatly facilitate the development of subsequent complex and irregularly shaped terahertz devices.

The research team composed of Prof. Li Ying and Prof. He Rujie from BIT is dedicated to the research and development of terahertz functional materials and devices, and has recently made a series of research progress. Firstly, achieving high-precision manufacturing of precursor-derived ceramics (PDC) is a challenge. The research team conducted research on the high-precision manufacturing process of PDC-SiOC microstructures using Projection Micro Stereolithography (PμSL) 3D printing technology. After systematic process exploration and optimization, they successfully prepared high-precision PDC-SiOC microstructures with structural feature sizes of only 52μm, exhibiting extremely high manufacturing precision and design manufacturing fidelity. The related research findings were published in the top journal in the field of ceramic materials, "Journal of Advanced Ceramics" (IF=18.6), under the title "Accuracy controlling and mechanical behaviors of precursor-derived ceramic SiOC microlattices by projection micro stereolithography (PμSL) 3D printing" (https://doi.org/10.26599/JAC.2023.9220818).

Fig.1 High-precision 3D printing manufacturing of PDC-SiOC microstructures.

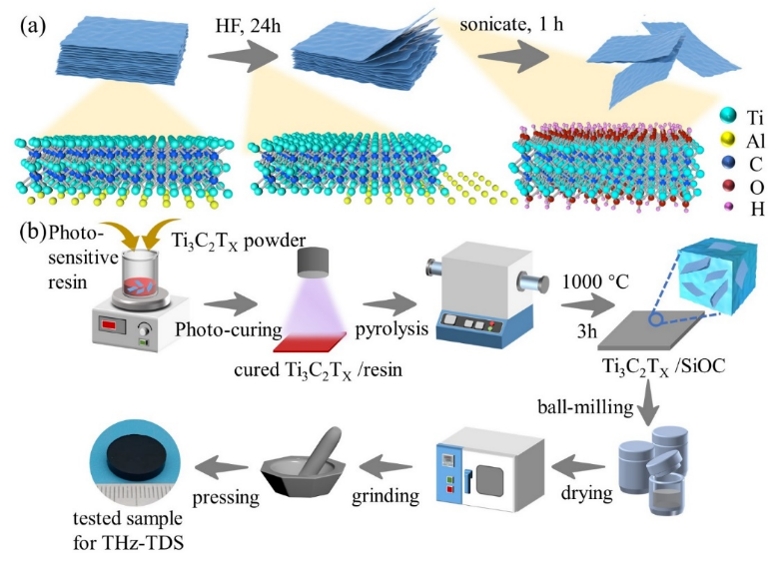

Next, in order to optimize the terahertz shielding performance of PDC-SiOC ceramics, the team optimized the synthesis of photocurable Ti3C2Tx MXene/SiOC (MSiOC) ceramic composite materials. Using acrylic-modified epoxy silicone resin as the precursor, and adding MXene powder obtained through acid etching, MSiOC ceramic composite materials were obtained after UV curing at a wavelength of 405 nm and vacuum pyrolysis. The MSiOC ceramic composite material has a "sandwich" structure composed of heterogeneous materials interlaced inside, which is conducive to the attenuation of electromagnetic waves, thereby exhibiting excellent electromagnetic shielding performance. The related research results were published in the top journal in the field of materials, the Journal of Materials Chemistry A by the Royal Society of Chemistry (IF=10.7, https://doi.org/10.1039/d4ta02495h), titled "Photocured Ti3C2Tx MXene/SiOC ceramic composite for electromagnetic interference shielding in the terahertz band", and were selected as a hot article.

Fig.2 Synthesis process of Ti3C2Tx MXene/SiOC ceramic composites suitable for photocurable 3D printing.

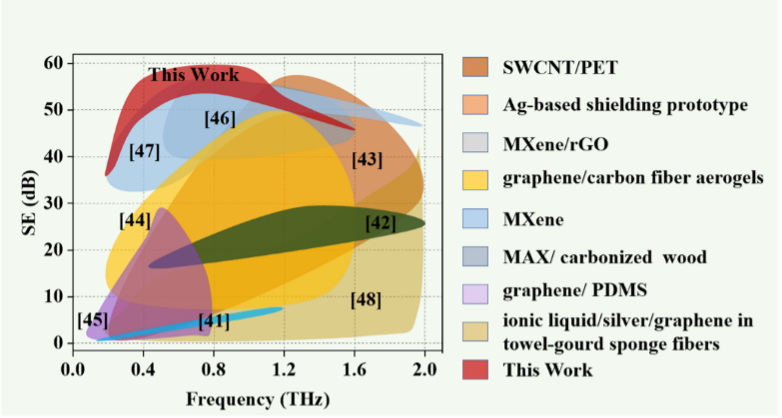

Finally, inspired by the honeycomb-like microstructures found in the wings of butterflies and other insects in nature, the research team designed biomimetic honeycomb microstructures of SiOC ceramics based on 3D printing and successfully fabricated them using Projection Micro Stereolithography (PμSL) 3D printing technology. The resulting SiOC ceramic biomimetic microstructures have a wall thickness of less than 50μm and a structural cell size of less than 200μm. Tests showed that the highest shielding effectiveness (SE) of the SiOC ceramic biomimetic microstructures reached 64.1dB, with a transmission rate below 1.4% from 0.2 to 1.6 THz. Additionally, over 97-99.8% of terahertz waves were absorbed within the range of 0.8 to 1.6 THz. These results indicate that the developed SiOC ceramic biomimetic microstructures possess excellent terahertz shielding performance and have innovative application prospects in the field of terahertz electromagnetic wave protection devices. The related research findings were published in the top journal in the field of materials, the Royal Society of Chemistry journal "Chemical Engineering Journal" (IF=13.3), under the title "3D printed SiOC architecture towards terahertz electromagnetic interference shielding and absorption"(https://doi.org/10.1016/j.cej.2024.155689).

“Regarding the link provided, I encountered some issues in parsing the webpage. This could be due to the link itself or network-related problems. I recommend checking the legitimacy of the web link and attempting to access it again. If the issue persists, it might be necessary to seek alternative means to access the content or contact the website's support for further assistance”, Professor He Rujie explained.

Fig.3 Design, 3D printing manufacturing, and terahertz shielding performance of biomimetic SiOC ceramic microstructures.

Fig.4 Comparative terahertz performance effects of biomimetic SiOC ceramic microstructures.