The woven composites are gradually used for aero-engine fan blades to satisfy the requirements of large bypass ratio, delamination resistance, and high damage tolerance. The outer contour of the fan blades has a significant twist geometry.

The twisted composite structure inevitably causes cross-sectional shape variation and path deflection of internal mesoscale yarns during the fiber-preform process. The irregular distribution of mesoscale yarns poses a challenge in investigating the mechanical behavior of this typical composite structure.

The typical CT scanning reconstruction method could realistically characterize the geometry of the yarns inside the structure. However, the scanning imaging quality strongly depended on the structural sizes. It is difficult to observe the meso-morphology of the entire complex structure at high resolution, and the cycle time is long and costly.

To efficiently and accurately characterize the mesoscopic yarn morphology of complex structures, the Institute of Advanced Structure Technology of BIT developed a digital mesoscopic modeling method for woven composite structures based on fiber-preform process simulation technology.

Prof. Liang Jun and Associate Prof. Ge Jingran are the senior authors of the paper, which appears in Composites Science and Technology. The paper’s first author is Liu Zengfei, a BIT graduate student in mechanics.

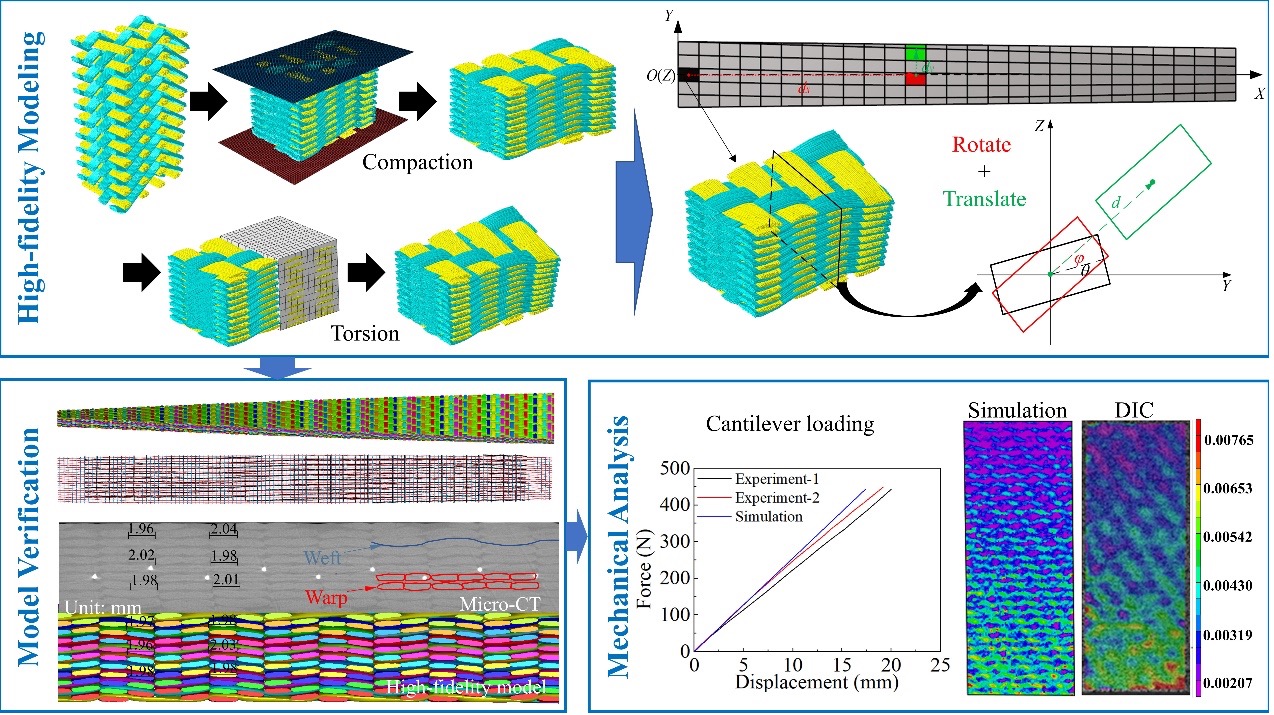

They simulated the compaction and torsional deformation of the fabric in the unit cell model with high fidelity using digital element fibers embedded into the matrix solid meshes. Subsequently, the path and cross-section of the yarn were accurately extracted using the Alpha-shapes algorithm and the digital element chain tracking method, and the solid geometric model of the twisted structure was reconstructed by combining the affine transformations.

Their established mesoscopic geometries of the twisted structures (yarn shape, path, and spacing) generally agreed with the realistic specimen results.

Furthermore, they mapped the local mesoscopic feature information of the twisted structure onto the macroscopic finite element model through geometric coordinates. The bending mechanical behavior of the twisted structure with different torsion angles was accurately predicted.

Their proposed digital analysis method for woven composite profiled structures can provide theoretical support for the early design and preparation of aero-engine fan blades.