Researchers from Beijing Institute of Technology designed a fabrication method that can significantly shorten the preparation periods and lower process cost of CMCs.

Ceramic matrix composites (CMCs) are successfully utilized in several industries, including aerospace and nuclear energy, owing to their exceptional ability to withstand high temperatures, high specific strength, and great fracture toughness. However, the extensive application of ceramic matrix composites has always been limited due to the long-period and expensive process.

The conventional techniques for preparing ceramic matrix composites consist of chemical vapor deposition/infiltration (CVD/CVI), Reactive melt infiltration (RMI), and precursor impregnation pyrolysis (PIP).

Nevertheless, the CVI process frequently needs thousands of hours, which significantly restricts its extensive use. Likewise, the PIP process also has comparable problems. Conventional precursor only achieves a ceramic yield of 30wt%-60wt%, indicating that numerous rounds (9-16) of the impregnation-pyrolysis are required for densification. In contrast to the CVI and PIP, the preparation period of RMI process is relatively short. However, the carbon fiber is commonly brought severely reactive damage by the liquid melt due to the high process temperatures ranging from 1600 to 2000℃.

“The lengthy preparation cycle is the main cause of CMCs' high cost. In recent years, many researchers have been consistently concerned about two major research hotspots: how to prepare CMCs with high throughput and how to shorten the densification period of CMCs,” says Professor Zhang Zhongwei at the Institute of Advanced Structure Technology, BIT.

In order to accomplish this, the teams of Professor Zhang Zhongwei developed a rapid densification ceramic matrix composite material preparation technology with an in-situ self-densification mechanism. The goal is to prepare ceramic matrix composites rapidly, inexpensively, and with a high throughput. The study named "A novel rapid fabrication method and in-situ densification mechanism for ceramic matrix composite"(10.1016/j.compositesb.2024.111881) was published in Composites Part B: Engineering.

Process Design

Over the past few years, there has been a constant stream of innovative rapid processes aimed at enhancing the densification efficiency of CMCs. For example, the ceramic slurry prepreg known as SICARBON with the assistance of the C3HRME project, which only needs to undergo 3 rounds of impregnation-pyrolysis after high-pressure sintering. Another rapid preparation technique called Nano Infiltration Transient Eutectic (NITE). The SiC prepreg manufactured by this method can be sintered at 1850 ℃/20MPa, resulting in a high density of 2.7g/cm3 for the prepared SiC/SiC composite.

“However, majority of these rapid processes rely on high-temperature and high-pressure sintering techniques, which still presents challenges due to high equipment costs and the difficulty of preparing CMCs with irregular shape,” says Zhang Yijun, the first author of this paper.

“Therefore, we proposed a rapid preparation technology named as ViSfP-TiCOP (High Viscosity Solvent-free Precursor Combined Elemental Titanium Controlled Pyrolysis),” says Professor Zhang Zhongwei.

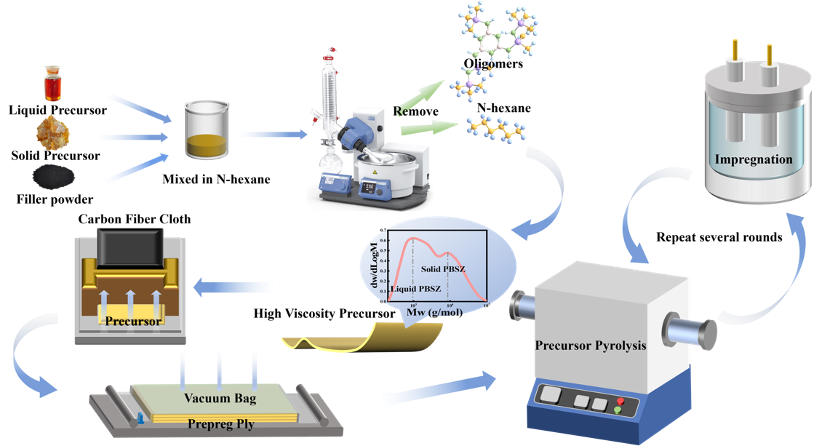

As shown in figure 1, the preparation process of ViSfP-TiCOP can involve four steps: precursor treatment, lamination of carbon cloth and precursor, layer-curing, and impregnation-pyrolysis.

Fig1. Process diagram for ceramic matrix composites using ViSfP-TiCOP

“This precursor, which has undergone high vacuum rotary evaporation treatment, contains nearly no solvents or volatile small molecules, resulting in extremely good chemical stability and ceramic yield,” says Zhang Yijun.

“The prepreg was prepared by combining ViSfP precursor with carbon fiber cloth. Contrary to hard ceramic-based green sheets, this precursor-based prepreg exhibits excellent adherence to metal molds and superior flexibility, which are attributed to the high viscosity and stability of ViSfP precursor,” he adds.

Compared with conventional CVI or PIP, ViSfP-TiCOP can shorten the densification period of CMCs to 200-400 hours. Meanwhile, large and irregular components do not significantly increase the densification period of ViSfP-TiCOP.

Densification Mechanism

The most efficient way to improve the densification efficiency of CMCs in conventional PIP is to employ fillers. However, typical inert fillers cannot achieve efficient sintering during the pressureless pyrolysis after being introduced in significant quantities to the precursor. Hence CMCs have to get densified by high temperatures and pressures. This inconsistency has always posed the most challenge in the entire research.

“We are evaluating whether we can abandon the current inert filler technique and look for fillers with higher sintering activity after recognizing this inconsistency,” says Zhang Zhongwei.

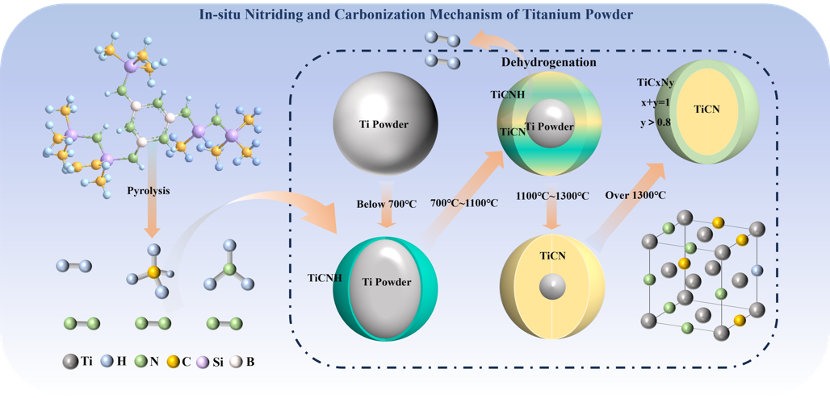

“We discovered that titanium's in-situ gas-phase carbonization and nitriding temperatures are comparable to the temperature range of conventional ceramic precursor pyrolysis. Therefore, we have decided to use elemental titanium to control the pyrolysis process” says Zhang Yijun.

Fig2. Mechanism of in-situ carbonization and nitridation of Ti during SiBCN-Ti pyrolysis.

As shown in Fig2, SiBCN-Ti has a rapid densification mechanism via in-situ gas-phase carbonization and nitridation. During the pyrolysis, the SiBCN precursor produces small molecules like CH4 and NH3. These molecules, which would have otherwise evaporated, are captured by Ti and increase volume.

During the pyrolysis at room temperature~1500℃, the in-situ gas-phase nitriding and carbonization mechanism of Ti can offer significant weight gain and volume expansion for the rapid densification of CMCs.

“ViSfP-TiCOP has the preparation advantage of pressureless, low-temperature (1200℃) conditions, which provides a rapid processing technology for CMCs,” Professor Zhang Zhongwei says.

The research was funded by the National Key Research and Development Program of China.