Fiber-reinforced polymer matrix composites are considered ideal materials for cryogenic fuel tanks of heavy-lift rockets due to their high specific stiffness/strength, superior stability, and low thermal conductivity. The design and application of fully composite tank structures are regarded as critical technological pathways to further enhance rocket payload efficiency. However, in ultra-low-temperature environments, factors such as changes in material component properties and thermal stress significantly impact the cryogenic mechanical performance and damage behavior of composites, posing challenges to the structural safety design and reliability evaluation of composite tanks. Current research often relies on ex-situ methods to observe the failure modes of composites at cryogenic temperatures, leaving the internal damage evolution behavior and mechanisms under such conditions still to be further uncovered.

Recently, under the guidance of Professor Fang Daining, Professor Lei Hongshuai, Associate Professor Wang Panding, and their team conducted a study on the failure mechanisms of composites at cryogenic temperatures using in-situ cryogenic μCT characterization. This research elucidated the damage evolution characteristics and influencing mechanisms within composite laminates under cryogenic environments. Their findings were published in the leading journal Composites Science and Technology (Impact Factor = 9.1) under the title, "Cryogenic damage mechanisms of CFRP laminates based on in-situ X-ray computed tomography characterization" (original link: https://doi.org/10.1016/j.compscitech.2023.110413).

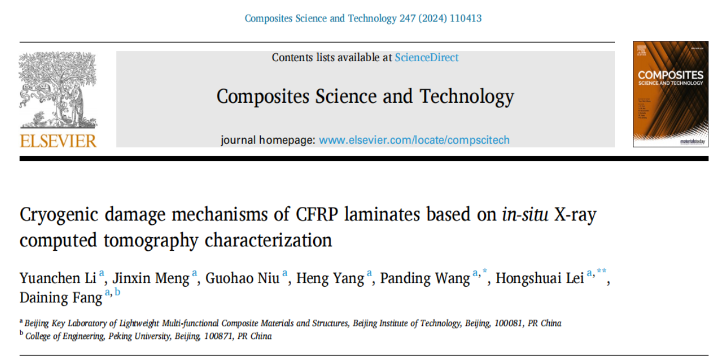

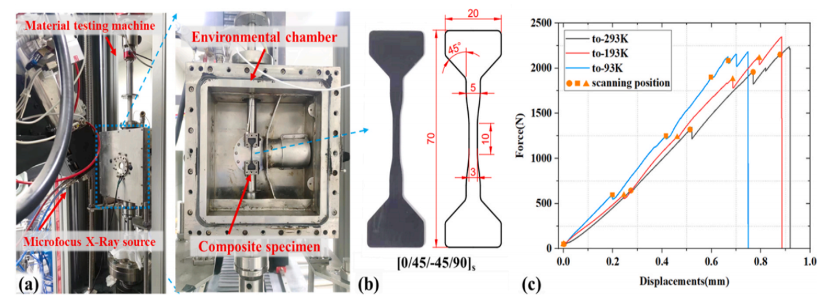

For the first time, this study employed in-situ cryogenic μCT characterization on composite laminates. Combined with multi-scale computational analysis, it explored the damage evolution behavior and influencing mechanisms within polymer matrix composite laminates under cryogenic environments. The research utilized an in-situ cryogenic micro-focus CT system to characterize the tensile process of laminates at representative temperatures (293K, 193K, and 93K), as shown in Figure 1. Based on the microstructural morphology, the damage types were categorized into matrix cracks in the 90° plies, matrix cracks in the -45° plies, and interlaminar delamination. The in-situ characterization results (Figure 2) revealed that cryogenic environments exacerbate the damage behavior of laminates, with significant increases in the volume fractions of matrix cracks in the 90° plies and delamination, as well as earlier initiation of damage during tensile loading. The damage morphology indicated that interlaminar delamination under both room and cryogenic conditions originated from the propagation of matrix cracks in the 90° plies. However, the generation of thermal stress under cryogenic conditions accelerated the crack propagation process.

Figure 1. Experimental setup for in-situ cryogenic mechanical μCT characterization

Figure 2. Damage evolution of laminates at different temperatures

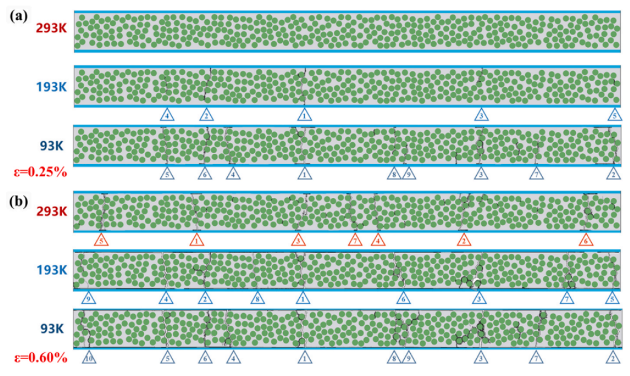

Building upon the in-situ characterization results and a temperature-dependent constitutive model of the resin matrix, the researchers developed a macro-micro multi-scale computational model to describe the initiation and evolution of laminate damage at different temperatures (Figure 3). Finite element simulation results showed that laminate damage intensifies with decreasing temperatures, accurately capturing the damage characteristics under cryogenic conditions. Based on the shear-lag model and numerical analysis results, the fracture toughness for transverse matrix cracking at cryogenic temperatures was obtained.

Figure 3. Comparison of calculated matrix cracks in 90° plies at different temperatures

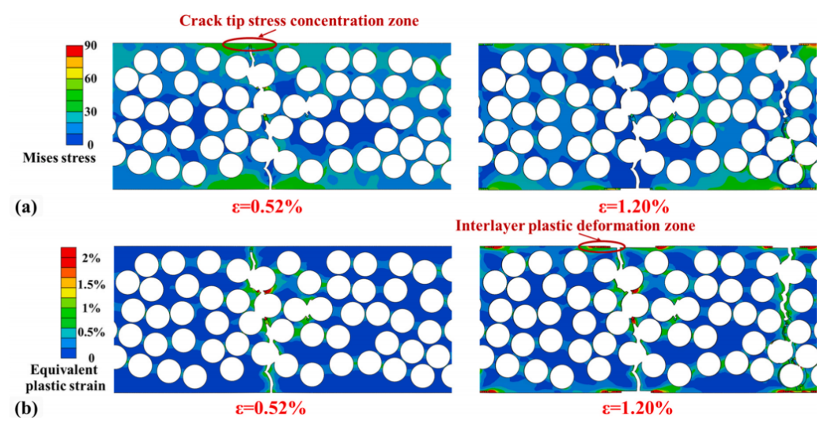

Furthermore, the study explored the underlying mechanisms of damage behavior under cryogenic conditions using the macro-micro computational model. Results demonstrated that matrix cracking is influenced by both matrix performance and thermal stress. While the increased strength of the resin matrix at low temperatures mitigates cracking, factors such as the increased matrix modulus and thermal stress promote both matrix cracking and interlaminar delamination. The brittle-ductile transition of the resin matrix at low temperatures was identified as the primary factor driving delamination. At room temperature, the matrix's plastic deformation effectively suppresses delamination crack propagation (Figure 4), while at low temperatures, the matrix's linear-elastic behavior leads to exacerbated delamination damage.

Figure 4. Stress and equivalent plastic strain distribution at the crack tip

This study provides new insights into the damage evolution mechanisms of polymer matrix composite laminates at cryogenic temperatures and analyzes the effects of ultra-low temperatures on laminate damage behavior through a macro-micro computational model. The findings offer theoretical and technical support for the safety design and reliability evaluation of structures operating in cryogenic environments. This work was supported by the National Natural Science Foundation of China and key research and development programs of the Ministry of Science and Technology.

Professor Lei Hongshuai, Associate Professor Wang Panding, and their team have previously conducted extensive research to address the lightweight and safety design requirements of cryogenic fuel tanks for rockets. Their work has focused on the mechanical, thermal, and leakage properties of composites under cryogenic conditions, yielding several representative publications:

[1] Meng et al. Mechanical properties and internal microdefects evolution of carbon fiber reinforced polymer composites: Cryogenic temperature and thermocycling effects.Composites Science and Technology 191 (2020) 108083. https://doi.org/10.1016/j.compscitech.2020.108083. (Effects of cryogenic and thermocycling conditions on composite mechanical properties)

[2] Meng et al. Leakage performance of CFRP laminate under cryogenic temperature: Experimental and simulation study. Composites Science and Technology 226 (2022) 109550. https://doi.org/10.1016/j.compscitech.2022.109550. (Cryogenic leakage performance and evaluation methods for composites)

[3] Li et al. Damage evolution characterization of glass fabric composites at cryogenic temperatures via in-situ tensile X-ray computed tomography tests. Composites Communications 35 (2022) 101326. https://doi.org/10.1016/j.coco.2022.101326. (In-situ characterization of damage evolution in composites under cryogenic conditions)

[4] Li et al. Cryogenic mechanics and damage behaviors of carbon fiber reinforced polymer composites. Composites Part A: Applied Science and Manufacturing 169 (2023) 107484. https://doi.org/10.1016/j.compositesa.2023.107484. (Multi-scale analysis methods for cryogenic mechanical properties of composites)

[5] Meng et al. Mode I fracture toughness with fiber bridging of unidirectional composite laminates under cryogenic temperature. Composites Science and Technology 246 (2024) 110386. https://doi.org/10.1016/j.compscitech.2023.110386. (Evolution mechanisms of interlaminar fracture toughness under cryogenic conditions)

[6] Li et al. Cryogenic thermal conductivity of carbon fiber reinforced polymer composite laminates. International Journal of Heat and Mass Transfer 226 (2024) 125521. https://doi.org/10.1016/j.ijheatmasstransfer.2024.125521. (Cryogenic thermal conductivity and predictive models for composites)