1.Research Background

Polyimide aerogels (PIAs) have received much attention in thermal protection material applications due to their excellent high-temperature resistance, wide operating temperature range, and flexibility. They are now considered a key material in high-end manufacturing. Its flexibility, excellent thermal stability, and high porosity make it the best insulation material for aerospace and space exploration equipment such as pneumatic retarders, recoverable space capsules, and ground probes. However, due to the complex application environment and usage requirements, balancing traditional PIA's high-temperature resistance and mechanical strength is still challenging. In addition, high shrinkage and poor molding capacity limit the multifunctional development of the material. Therefore, designing the macroscopic shape and microstructure of aerogel is necessary to achieve low shrinkage, strong insulation, and high mechanical strength.

Based on the above questions, Associate Professor Xu Baosheng and his team published a paper entitled “Ultralight, low-shrinkage copolyimide aerogels with excellent mechanical strength for flexible thermal protection” in the TOP Chemical Engineering Journal (IF:13.3). Flexible and low shrinkage PIAs with excellent thermal insulation properties, mechanical properties, and high-temperature resistance were synthesized by a copolymerization modification-chemical iminization strategy. By taking full advantage of the fact that the copolymer 3,3 ', 4,4 '-biphenyl tetracarboxylic acid dianhydride has rotatable single bonds, increasing the free volume of the involved chains, PIAs achieve a remarkable transformation from brittle to high flexibility. At the same time, the interaction between the nano-chain segments involved in the reaction contributes to the formation of a three-dimensional network structure with high node connectivity and robust cross-linking, which improves the mechanical strength of PIA and effectively reduces the drying shrinkage. Overall, this study introduces a new method for developing flexible, low-shrinkage polymer materials with excellent thermal insulation and mechanical properties, with great potential for applications in aerospace exploration work. The corresponding author of this paper is Xu Baosheng, associate professor, PhD supervisor, and vice president of the Institute of Advanced Structural Technology, Beijing Institute of Technology. Mainly engaged in the research of new anti-thermal insulation materials and structures, including new aerogel, special coating, low-temperature resistant resin materials, and new flexible anti-thermal insulation materials and structures.

2.Research Contents

Fig. 1. Synthesis scheme, molecular structure, and physical picture of PIAs. (a) Schematic of PIA preparation. (b) Schematic of molecular-chain assembly during PIA synthesis. (c) Reaction of an aromatic diamine with aromatic dianhydride. (d) Photograph of P0B1–PIA with a 4.546 mm thickness.

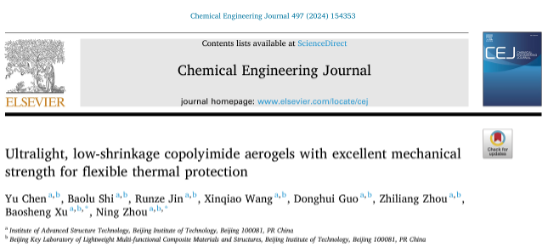

Fig. 2. PIA characterization: (a) FTIR spectra of PIAs with different dianhydride monomer ratios; (b) 13C NMR spectra of P1B3–PIA; (c) SEM microcosmic cross-sectional morphology of PIAs: c1–c5 represent the microstructural morphology of PIA when the proportion of BPDA in dianhydride increases from 0 % to 100 %, and c6–c10 are the corresponding high-magnification micromorphology of PIAs.

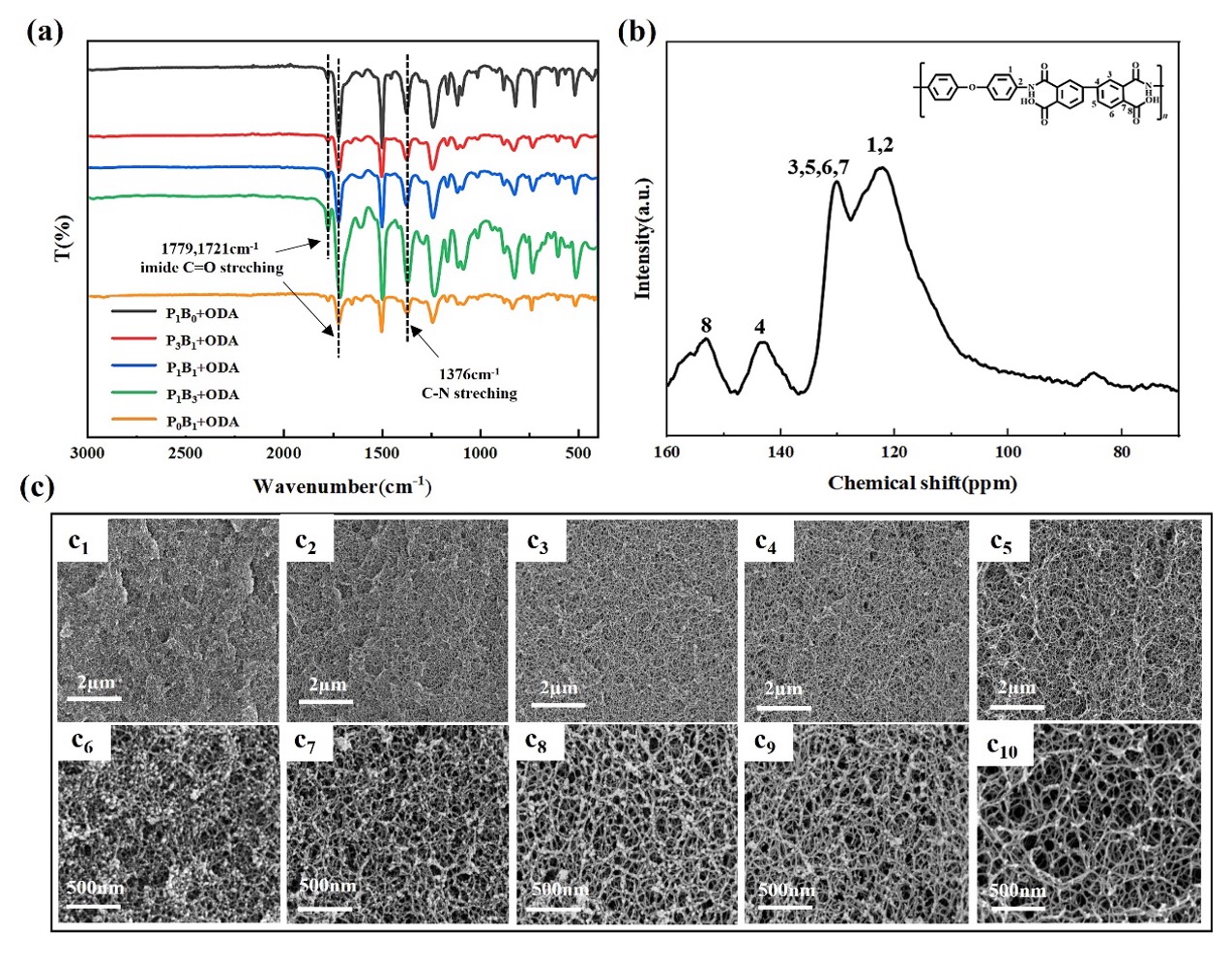

Fig. 3. PIA thermogravimetric analysis results: (a) TGA and (b) DTG curves in air; (c) TGA and (d) DTG curves in N2; (e) DSC-based Tg curve.

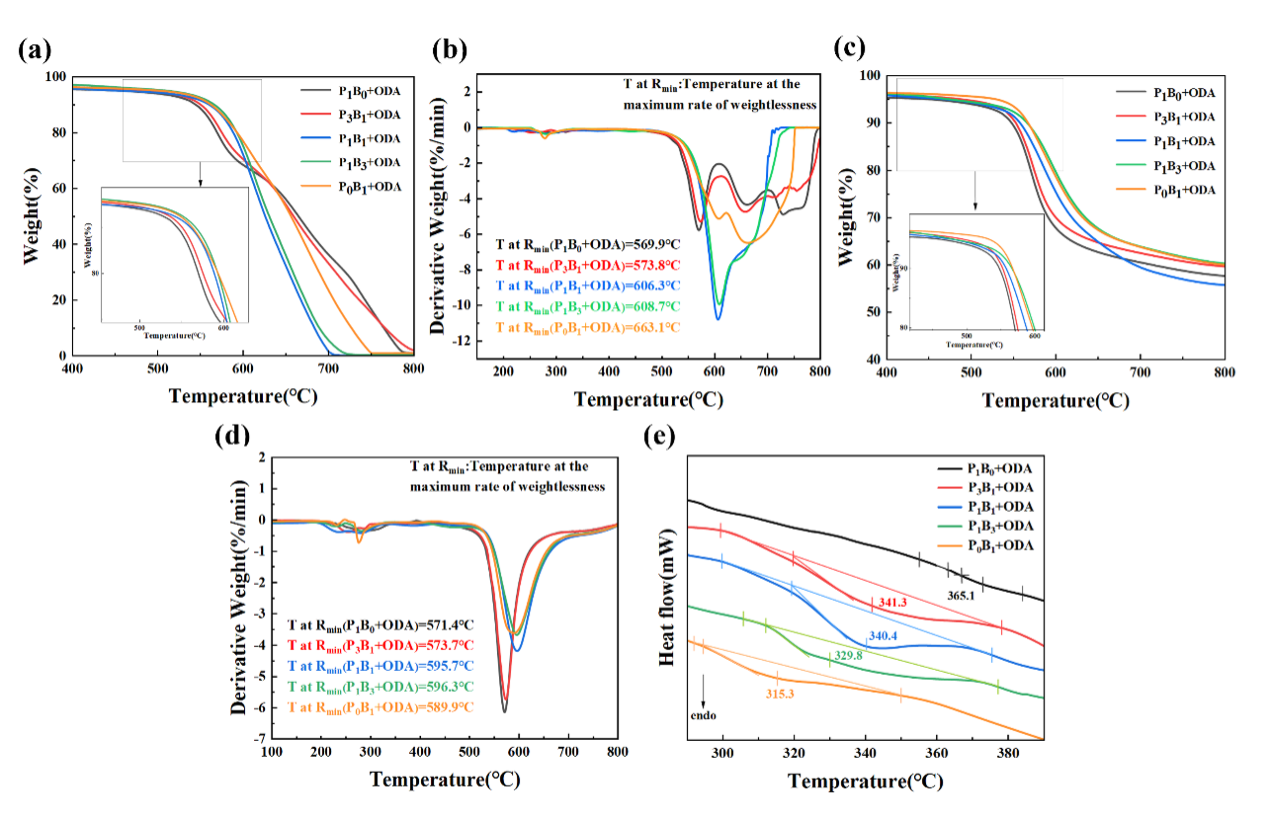

Fig. 4. Flexibility and temperature resistance of PIAs. (a) Flexibility characterization of P1B0–PIA. (b) Temperature resistance test and characterization of the P1B1–PIA film flexibility after high-temperature treatment.

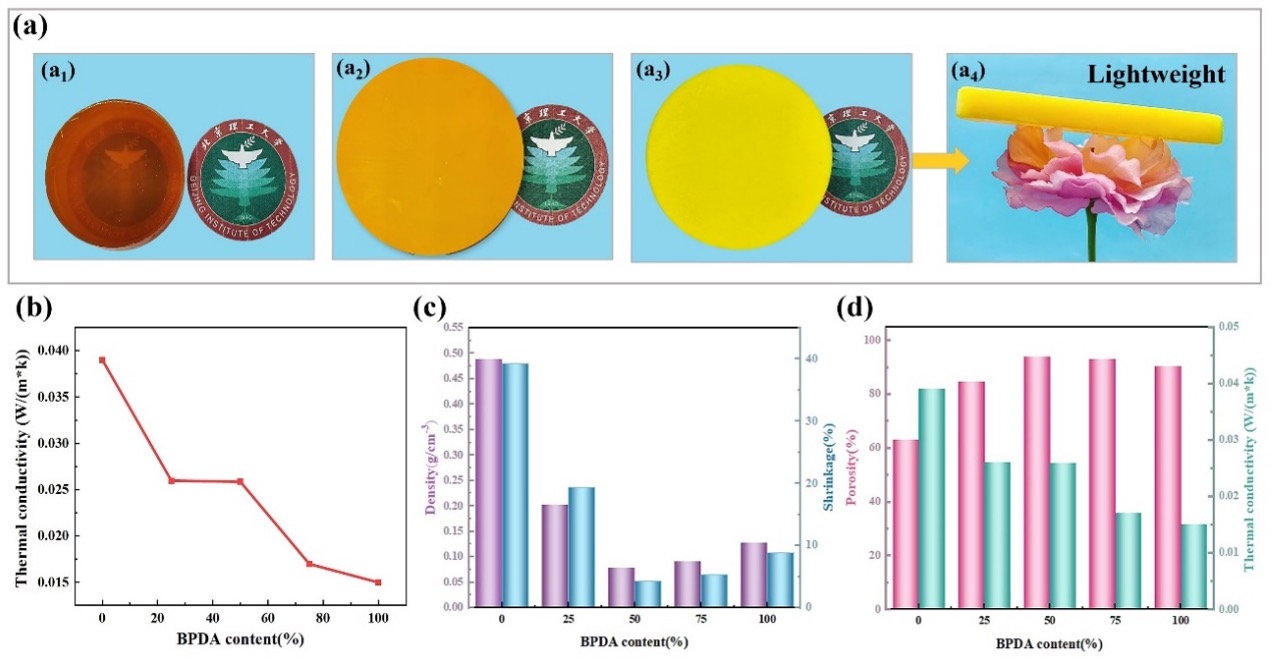

Fig. 5. Images of PIAs, variations of thermal conductivity, and variations of physical properties. (a) Morphology of PIAs with different dianhydride monomer ratios: (a1) P1B0–PIA, (a2) P1B1–PIA, and (a3) P0B1–PIA; and (a4) photographs demonstrating the lightweight of P0B1–PIA. (b) Variation of thermal conductivity with the BPDA proportion. (c) Variation in density and shrinkage with varying BPDA proportion. (d) Variation of porosity and thermal conductivity with the BPDA proportion.

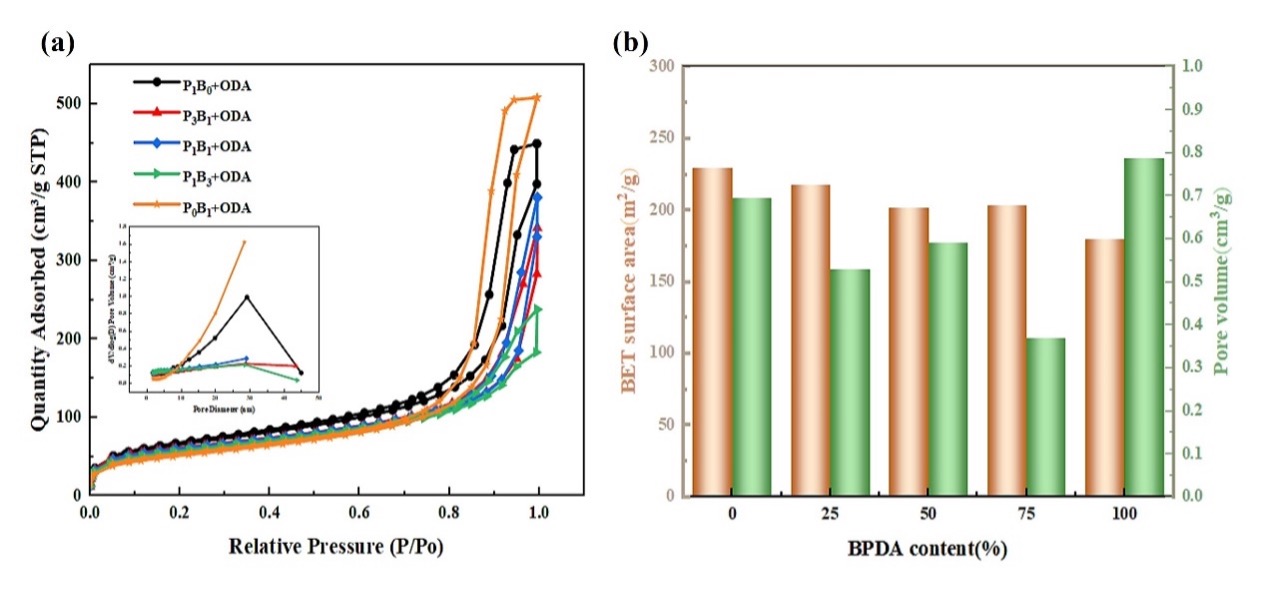

Fig. 6. BET test results of the PIAs: (a) pore size distribution and specific surface areas of PIAs prepared with different dianhydride monomer ratios and (b) variation of specific surface area and adsorbed total pore volume with varying BPDA proportion.

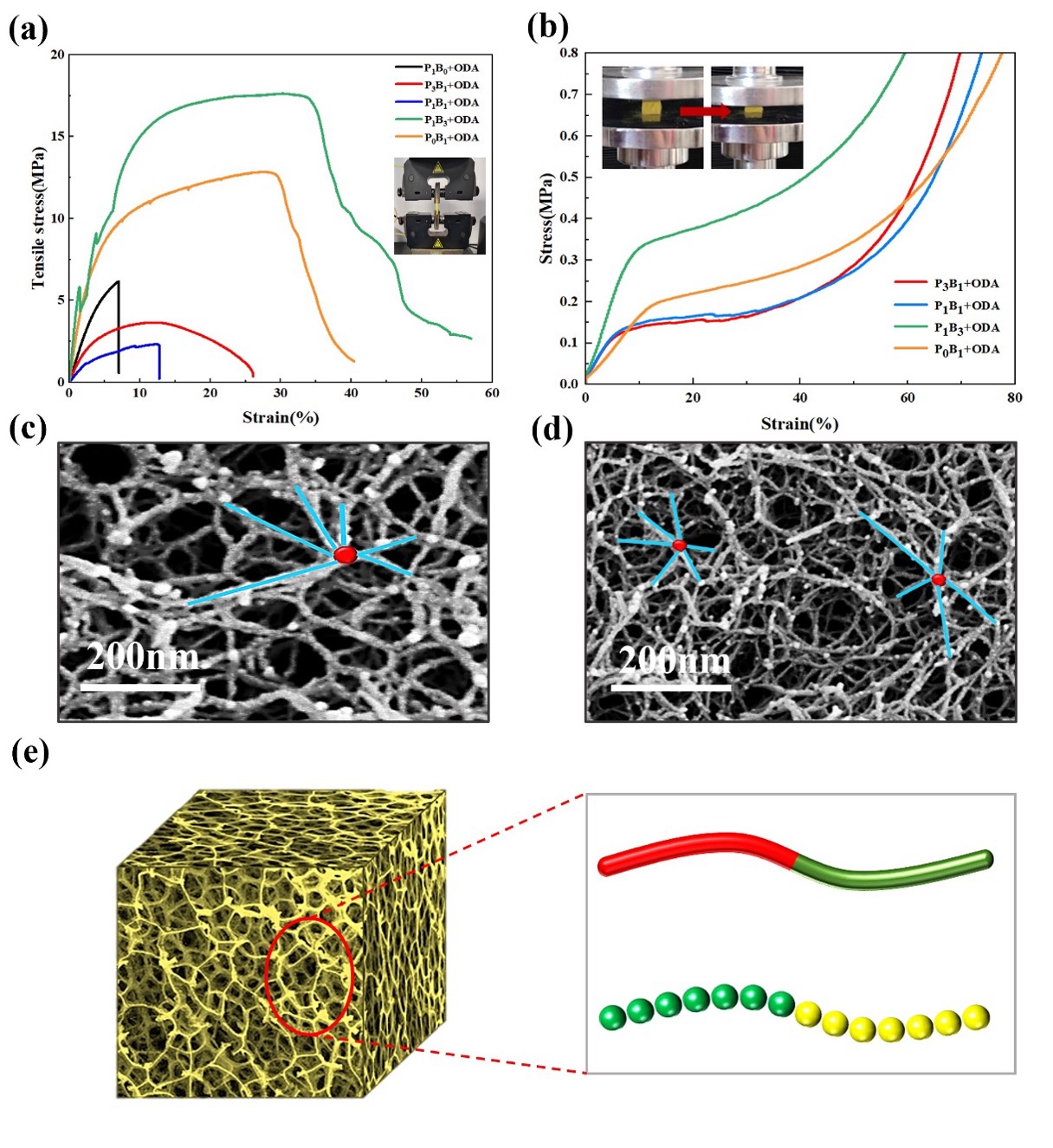

Fig. 7. Mechanical properties and microstructures of PIAs. (a) Tensile and (b) compressive stress-strain curves of PIAs with different dianhydride monomer ratios. (c and d) Localized SEM images of random 3D networks with highly interconnected nodes in P1B3–PIA and P0B1–PIA, respectively. (e) Schematic of the macroscopic 3D network and block molecular-chain structure in PIAs.

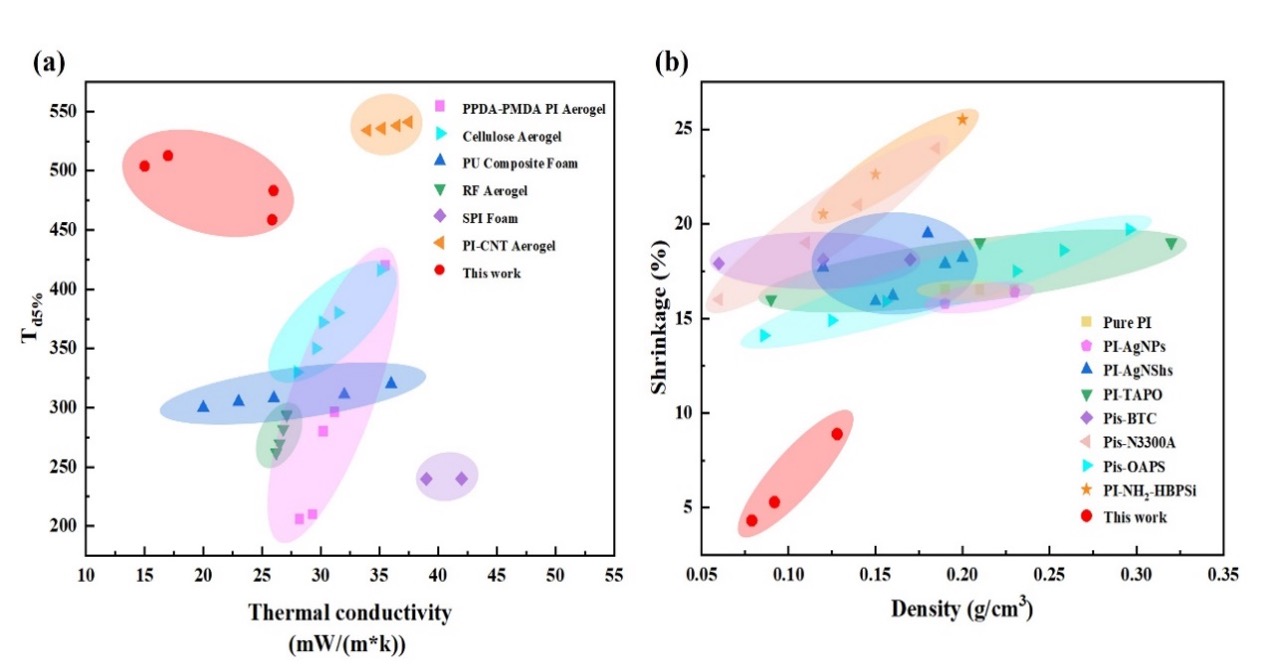

Fig. 8. Comprehensive properties of developed PIAs: (a) comparison of thermal conductivity and temperature resistance of our PIAs with those of aerogels and foams reported previously; (b) comparison of density and shrinkage of our PIAs with those of aerogels reported previously.

3.Conclusion

Herein, PIAs with exceptional comprehensive performance were prepared through copolymerization modification–chemical imidization. The effects of varying dianhydride monomer ratios on PIA density, shrinkage, porosity, thermal stability, thermal conductivity, and mechanical properties were investigated. Block-copolymerized PIAs exhibited exceptional thermal, mechanical, and insulation properties, boasting impressive thermal stability with a Td5% value of 512.6 °C in air and thermal conductivity of 15.1 mW·m−1 K−1. These characteristics position them as ideal candidates for advanced thermal management materials. Further, the prepared PIAs showed excellent mechanical properties, with the tensile strength and modulus of P1B3–PIA reaching 17.633 and 468.41 MPa, respectively, exceeding those of the commercial PI foam TEEK-HH by >40 times at a similar density. The flexibility, low density (0.079 g/cm3), high mechanical strength (17.633 MPa), high-temperature stability, and effective thermal insulation properties of the PIAs enable their diverse potential applications in aerospace and automotive industries, such as in high-temperature-resistant fairings, aerodynamic reducers, retrievable capsule insulation materials, and insulating structural materials with various shapes.

4.Paper citation

Chen, Y., et al., Ultralight, low-shrinkage copolyimide aerogels with excellent mechanical strength for flexible thermal protection. Chemical Engineering Journal, 2024. 497: p. 154353.

DOI:https://doi.org/10.1016/j.cej.2024.154353