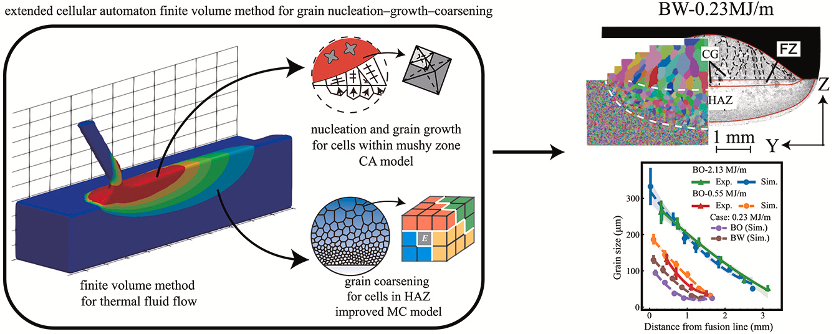

Fig: Illustration of the basic idea of the proposed method and the validation

Additive manufacturing (AM), or 3D printing, is a transformative technology that creates objects from the ground up by depositing materials layer by layer, offering vast potential for customized production, reduced waste, and the ability to manufacture complex designs that traditional methods cannot achieve.

To tailor the properties of the fabricated parts, scientists have developed numerical methods to understand the process–microstructure–property relationship in AM. However, modeling the microstructure evolution in AM is still challenging and needs to be adequately addressed.

The wire-based AM process, which has the highest heat input in the AM process, demonstrates more significant epitaxial grain growth in the fusion zone (FZ) and grain coarsening in the heat-affected zone (HAZ). However, there is a lack of adequate development in numerical methods to address the grain structure evolution within the FZ and HAZ.

To solve the problem, BIT researchers proposed an extended cellular automaton finite volumemethod to predict the microstructure evolution in wire-based AM.

The proposed method integrates a finite volume method with the CA model and an improved MC model. The finite volume method provides temperature fields and melt pool morphology for predicting grain structures. The CA model is applied to simulate grain nucleation and growth in the mushy zone, while the improved MC model is proposed to predict grain coarsening in the HAZ.

The research was published in the journal Additive Manufacturing titled “Additive Manufacturing: An extended cellular automaton finite volume method for grain nucleation–growth–coarsening during the wire-based additive manufacturing process.” The corresponding author is Professor Lian Yanping from Beijing Institute of Technology, who has been engaged in research in computational mechanics theory and algorithms for a long time.

Microstructure evolution

The research focused on modeling epitaxial grain growth in the FZ and grain coarsening in the HAZ. For the epitaxial grain growth in the FZ, the CA model has been successfully applied to predict grain structures during many metal AM processes; and the MC model is often applied to predict the grain coarsening in the HAZ.

Therefore, addressing the coupling of MC and CA models to develop an efficient numerical method is worth investigating to solve the challenge of monolithically predicting grain growth in the FZ and coarsening in the HAZ.

Often, the easier way to use coupling methods is one-way coupling: the result of one model is transferred as input to another model. This means that grain growth and coarsening occur successively. However, for the AM process, grain growth and coarsening occur simultaneously.

Thus, it is crucial to use a strong coupling scheme to consider the simultaneous occurrence of grain coarsening and epitaxial grain growth phenomena when seeking accurate predictions of grain structures.

A two-way coupling strategy requires alternating between the two models and exchanging simulation results in a single time step. However, the iteration time steps in MC are virtual and not proportional to physical time, which is different from the physical time in the CA model. This makes it difficult to unify the time steps of the two models.

The researchers proposed a two-way coupling scheme between the CA and improved MC models, which are synchronized in time marching using a proposed alternatively multi-time step scheme.

Additionally, the CA model provides some meaningful physical information in the two-way coupling strategy, i.e., grain orientation and texture, which is not considered in the MC model. The researchers proposed an improved MC model to consider the physical information provided by the CA model.

This allows the proposed method to effectively combine the advantages of the CA model and MC models in predicting the grain nucleation and growth in the mushy zone and coarsening in the HAZ, respectively.

After validating the accuracy of the proposed method, the results showed that the grain coarsening substantially affects the grain structure of the subsequent layers and cannot be ignored.

In the long run, they hope to use this work as a stepping stone toward the comprehensive understanding of the process–microstructure–property relationship in metal AM processes, and assist in optimizing process parameters to achieve builds with expected mechanical properties.